Magnezix

Bioabsorbale Metallic Implants

MAGNEZIX® implants manufactured from this completely innovative material have comparable mechanical stability to previous metal systems such as screws and Kirschner wires made out of titanium or steel but are successively resorbed by the body and replaced by bone material. Our implants are therefore the first transformable metal implants in the world.

MAGNEZIX® is a magnesium-based alloy, which although having metallic properties, is completely resorbed in the body and is transformed at the same time into bone tissue. The biomechanical properties of MAGNEZIX® are very similar to those of human bone. The alloy is derived from the MgYREZr alloy system pursuant to DIN EN 1753, and has a magnesium concentration of over 90 %, a grain size of less than 10 µm, and is manufactured using a unique and highly sophisticated powder-metallurgical process. This enables it to achieve a tensile strength which is very much higher than that of resorbable polymers (PLA/PGA), namely in the ideal range between bone and titanium.

MAGNEZIX® implants manufactured from this completely innovative material have comparable mechanical stability to previous metal systems such as screws and Kirschner wires made out of titanium or steel but are successively resorbed by the body and replaced by bone material. Our implants are therefore the first transformable metal implants in the world.

MAGNEZIX® is a magnesium-based alloy, which although having metallic properties, is completely resorbed in the body and is transformed at the same time into bone tissue. The biomechanical properties of MAGNEZIX® are very similar to those of human bone. The alloy is derived from the MgYREZr alloy system pursuant to DIN EN 1753, and has a magnesium concentration of over 90 %, a grain size of less than 10 µm, and is manufactured using a unique and highly sophisticated powder-metallurgical process. This enables it to achieve a tensile strength which is very much higher than that of resorbable polymers (PLA/PGA), namely in the ideal range between bone and titanium.

Some studies were also able to show that magnesium alloys have osteoconductive properties. Verification has also been provided that the degradation products of magnesium have anti-bacterial and infection inhibiting properties.

MAGNEZIX® has good compatibility: it contains neither nickel nor aluminium and there are no allergies with respect to the alloy constituents (high biocompatibility). And there is also no harm done to the body by the absorbed magnesium because it is resorbed over a long period of time and can be ignored when compared to the total amount of magnesium in the body: around 150 mg magnesium per implant (CS 3.2, 20 mm length) roughly corresponds to the amount in three large bottles of standard mineral water and is well below the levels found in Mg tablets swallowed as a nutritional supplement.

The biomechanical properties (such as modulus of elasticity and tensile/compressive strength) of magnesium are closer to the human bone than titanium and are clearly superior to polymers – the ideal material for an innovative implant.

THE “IDEAL” IMPLANT DISAPPEARS ON ITS OWN

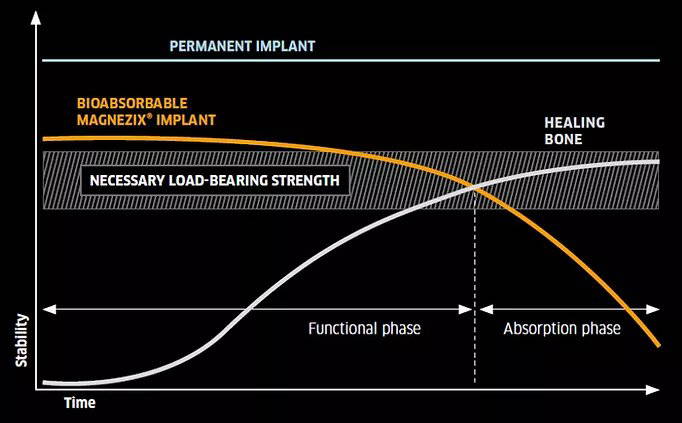

MAGNEZIX® is based on a magnesium alloy and boasts metallic properties (stability, strength, radiological visibility), but can nevertheless be completely resorbed in the body and replaced by the body’s own tissue. As regeneration proceeds and the load-bearing strength improves, the healing bone continuously bears increasing loads and adjusts to the stress it is exposed to, which means that the course of healing can be positively influenced.

Patients are not happy about metal remaining permanently in their bodies after an operation. Moreover, they are also not keen on having another operation to remove the metal because they are aware of the surgical and infection risks, and wish to remain mobile. As a material for implants, MAGNEZIX® boasts the ideal combination of properties for a temporary but still stable load-bearing component, for which doctors have waited for a long time.

Heal first, then disappear. MAGNEZIX® stabilizes the healing bone until it can carry again enough load alone (functional phase). After that, the implant is gradually transformed by the body (absorption phase). Permanent implants, on the other hand, remain permanently in the body and can cause problems or follow-up complications – MAGNEZIX® is converted to endogenous bone tissue.

A NEW DIMENSION IN IMAGING DIAGNOSTICS

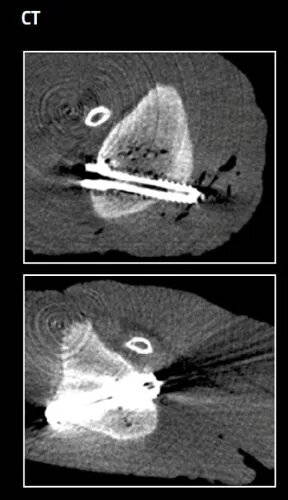

MAGNEZIX® screws and pins are metallic implants. Nevertheless, interference signals in computer tomography, as well as MRT diagnostics, are reduced to a minimum – the implants generate hardly any artefacts. This considerably improves the ability of surgeons and radiologists to assess the images. Moreover, unlike conventional products made of steel or titanium, MAGNEZIX® implants do not show any significant temperature increase during MRT.

MAGNEZIX® (top image) generates considerably fewer artefacts and/or interference in imaging diagnostic methods when compared to titanium (bottom image).

OSTEOCONDUCTIVE AND INFECTION INHIBITING – MAGNEZIX®

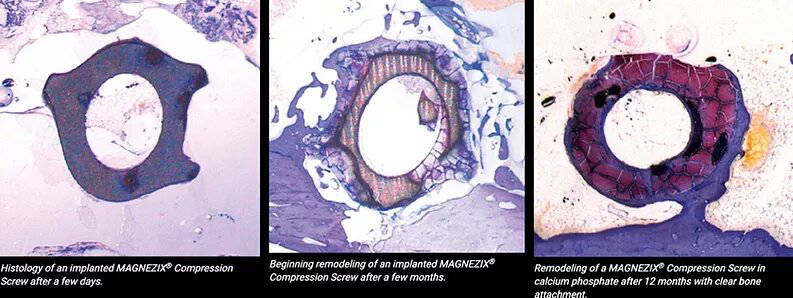

MAGNEZIX® boasts osteoconductive properties. In-vitro findings not only revealed the high vitality of human osteoblasts (bone cells), but also even stimulation in proliferation tests (growth and proliferation). Both the resorption of the implant as well as the formation of new bone (osteoid) on the surface of the resorbed implant were confirmed and verified in histological photographs. The resorption of the magnesium contained in a MAGNEZIX®implant takes place via corrosion, which leads to the creation of an alkaline environment in the direct vicinity of the implant, in which bacteria have lower survival chances – which is why MAGNEZIX® is expected to have anti-infection properties.

The histological images show the phases of the transformation process of a MAGNEZIX® CS in rabbit animal models. The image below shows a cross-section of the hollow compression screw at various post-operative times.

Left: Histology of an implanted MAGNEZIX® Compression Screw after a few days.

Centre: Beginning remodelling of an implanted MAGNEZIX® Compression Screw after a few months.

Right: Remodelling of a MAGNEZIX® Compression Screw-in calcium phosphate after 12 months with clear bone.

If you are interested in finding out more

about Magnezix get in touch